Dodge

Safe, Rugged, Reliable... Welcome to Dodge

Since 1878, Dodge has been discovering solutions that make industry operations easier. From the Independence Split Wood Pulley to Smart Sensors for mechanical products, our innovations have evolved to push entire industries forward. Every day, we honor the legacy of innovation that originated with our founder, Wallace Dodge. And we eagerly continue looking ahead to what we can achieve next.

Reliably equip our customers with the safest, highest quality mechanical power transmission solutions to achieve their strategic goals. We don’t just make products. We provide expert solutions. When you work with Dodge, you get more than just a piece of high-quality equipment. You get engineering guidance and solutions from our industry and application experts who know how to help facilities run more safely and efficiently. For over 140 years, we have built a strong foundation of industry leadership, innovation, and best-in-class service all part of the Dodge legacy.

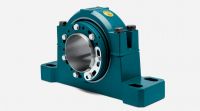

Mounted Bearings[edit | edit source]

Fully Assembled Bearings, Ready for Industrial Use. Dodge bearings offer innovative designs, patented features, and consistent performance with a wide range of shaft attachment methods, rolling elements, housings, and seal choices.

Ball Bearings[edit | edit source]

When it comes to reliable service and low maintenance, Dodge mounted ball bearings are unmatched in the industry. Dodge mounted ball bearings are available in any of our proven locking devices, including our exclusive 65-degree setscrew locking system, eccentric locking collars, D-LOK™ concentric clamp locking system, and our patented GRIP TIGHT® adapter mounted ball bearing.

Spherical Roller Bearings[edit | edit source]

For nearly 100 years, industry’s leading producers have depended on Dodge roller bearings to handle their conveyance and power transmission needs. Our reputation for quality and reliability has remained throughout the years and from that, innovation and engineering a complete family of roller bearings has evolved. Today, our spherical roller bearings offer innovative designs, consistent performance and quality, a wide range of shaft attachment methods, and patented products such as Safety Mount to continue providing value to our customers.

Tapered Roller Bearings[edit | edit source]

Industry-trusted and industry-proven for 100 years, Dodge Type E-XTRA, EXL, TAF, Double Interlock, and Type K double row mounted tapered roller bearings come in a variety of housings styles and mounting configurations to meet your application needs. All Dodge Type E Family bearings ship factory-ready to incorporate Dodge Smart Sensor next generation condition monitoring with customizable alerts and alarms via iPhone, Android, or Cloud based platform, ready to detect vibration and temperature spikes. Split housed configurations like Type E-XTRA enhanced EXL and SAF dimensioned TAF offer up to five degrees of misalignment and expansion capability.

Sleevoil[edit | edit source]

Dodge Sleevoil RTL Series hydrodynamic bearings provide exceptionally strong performance in high heat applications. The liner design offers excellent radial and thrust load capacities.

Journal Bearings[edit | edit source]

Dodge offers a wide variety of journal bearings that are uniquely engineered to provide reliable performance, even in the harshest environments. Ideal for mining, air handling, unit handling, high temperature, and food and beverage applications, our journal bearings feature patented technologies that reduce maintenance and ensure long service life.

Take-Up Frames[edit | edit source]

Dodge offers eight take-up frame types available from stock, with standard frame travel from 1½ to 60 inches. Take-up frames allow for the mounting of Dodge ball, roller, and sleeve bearings. Our take-up frames are made to provide and maintain tension and shaft centers on a variety of belt and chain-type conveyors.

Circulating Oil Systems[edit | edit source]

In many applications, there are limitations to oil ring lubrication—especially during startup, slow speed conditions, and in the presence of solid contamination. Adding an external circulating oil system can overcome these limitations while also offering benefits to bearing reliability, cooling, and easier condition monitoring.

Enclosed Gearing[edit | edit source]

Engineered for Reliability : Dodge enclosed gear products deliver industry-leading performance in some of the most demanding applications, featuring innovations that provide customers maximum up time with less maintenance.

Torque-Arm[edit | edit source]

With 60 years of proven dependability and more than 1.8 million units in service throughout the world, Dodge Torque-Arm speed reducers are the standard of the industry and the benchmark to which others are compared. The TXT Torque-Arm is a shaft mount helical gear reducer that mounts directly to the driven shaft with multiple accessories available to produce versatility, cost savings, and long life. A long list of standard features makes this reducer suitable for a wide range of environments, right off the shelf.

Quantis[edit | edit source]

The Dodge Quantis Product Line is a modular gear drive engineered for flexibility and power density in a compact housing design. A wide variety of mounting configurations and accessories make the Quantis an ideal solution for many industrial applications. Stainless steel and the exclusive E-Z Kleen finish are available for tough washdown applications.

Motorized Torque-Arm II[edit | edit source]

Dodge Motorized Torque-Arm II shaft mount reducers deliver longer life in demanding applications. Designed with a patented harsh duty sealing system, twin tapered bushings, and the highest torque rating per case size, these reducers provide maximum reliability with less maintenance to increase operating time and lower total cost of ownership.

Tigear-2[edit | edit source]

The Tigear-2 line of single reduction, right angle worm gear reducers has been engineered to provide maximum value and durability. Shipped from the factory filled with H1 food grade synthetic lube and a ventless sealing system, the Tigear-2 requires no routine oil changes. An overhung load capacity that is unmatched in the industry provides long life in conveying applications. The exclusive E-Z Kleen finish and food safe stainless steel are available for tough washdown applications.

Maxum[edit | edit source]

The Dodge Maxum XTR reducer is a compact, power-dense, high-torque-speed reducer designed for reliable performance. No other reducer can match it in design, performance, or value. With a rugged, ductile iron housing, this reducer meets or exceeds AGMA standards and features a premium sealing system as standard. It’s a Helical in-line base mount gear reducer offering flexibility in mounting design, increased horsepower, and torque ratings with improved power density.

MagnaGear[edit | edit source]

The MagnaGear XTR reducer’s simple, power-dense design offers superior torque ratings and assures increased reliability in a more compact, economical, and heavy-duty package. MagnaGear XTR is manufactured to provide maximum reliability in tough applications and to improve your total cost of ownership.

Controlled Start Transmission[edit | edit source]

The Controlled Start Transmission (CST) system is a multi-stage gear reducer combined with a wet brake acting as a clutch unit and a hydraulic control system. It’s designed for smooth-starting high inertia loads. The output torque from a CST unit is controlled via a hydraulic control system. By varying the hydraulic pressure applied to the clutch, the output torque can be varied. Dodge services and upgrades are available for Dodge CST gear reducers. All work is performed using genuine factory parts built to factory specifications by Dodge factory employees.

Couplings[edit | edit source]

Manufactured by Dodge for Over 100 Years : The Dodge coupling product line can offer a solution to almost any need. Whether it’s for an elastomeric or metallic design, Dodge can provide a coupling with the potential to increase torque capacity, accommodate shaft misalignment, extend life, and put an end to unexpected downtime. Our couplings are one of the many reasons we’ve earned a reputation for developing innovative products that lower our customer’s total cost of ownership.

Elastomeric Couplings[edit | edit source]

Dodge elastomeric couplings are available in innovative designs such as the Raptor (split-tire), and popular styles such as the Para-Flex (tire), D-Flex (sleeve), and StarFlex (jaw). This large product offering delivers coupling solutions for virtually any application such as pumps, compressors, and fans.

Metallic Couplings[edit | edit source]

Dodge metallic couplings are available in flexible designs such as Grid, Gear, and Chain, as well as rigid designs such as Taper-Lock Rigid, Ribbed Rigid, and Moment couplings. This broad offering delivers solutions across the torque spectrum, from pumping applications to packaging with Dodge enclosed gearing for high-torque conveying applications.

Mechanical Soft Starts[edit | edit source]

Dodge fluid couplings are most commonly used on remote location conveyor drive applications in the mining, aggregate, cement, and power generation industries where controls and drives are difficult to power, program, and maintain.

Conveyor Components[edit | edit source]

A Worldwide Reputation for Reliability and Quality : Dodge offers a variety of pulley types, styles, and different options—from CEMA (Conveyor Equipment Manufacturers Association) standard to large, highly engineered pulleys—in addition, to complete pulley assembly packages made from the best components in the business.

Drum Pulleys[edit | edit source]

Dodge heavy duty and mine duty extra (MDX) drum pulleys deliver high performance and are available when you need them. Available from stock in many common sizes or custom-made, Dodge heavy duty drum pulleys meet or exceed CEMA application standards for use with conveyor belts rated up to 750 PIW (Pounds per Inch of Belt Width) by 131 kN/m.

Wing Pulleys[edit | edit source]

Dodge wing pulleys deliver high performance and are available from stock in many common sizes. Dodge wing pulleys meet or exceed CEMA application standards for use with conveyor belts rated up to 450 PIW by 78 kN/m.

Lagging[edit | edit source]

Dodge conveyor pulleys can be provided with high quality lagging, designed to ensure maximum belt and pulley life in tough applications. Dodge has the expertise to offer a full variety of lagging options, including vulcanized, cold bond, and weld-on lagging.

Bushings and Hubs[edit | edit source]

Dodge HE bushings have unique features and a high-endurance design that extend conveyor pulley life. Dodge also manufactures XT bushings, which are interchangeable with bushings found on competitive conveyor pulley products. Hubs are useful for welding into fan rotors, impellers, agitators, etc., which require secure mounting to the shaft.

Bushings, Hubs, & Collars[edit | edit source]

Designed to Do More with Your Dodge Equipment : Bushings, hubs, and collars are accessories for mechanical drive components. Bushings are linings for a round hole between two parts, which help regulate the transmission of energy. Hubs are useful for welding into fan rotors, impellers, agitators, etc., which require secure mounting to the shaft. Collars are used to accommodate components on power transmission application and are available in solid steel and solid iron.

Belted Drives[edit | edit source]

Made for Safe, Efficient Production : V-belts and synchronous drives are widely used to change speeds and transmit torque from a drive, such as an electric motor to the driven equipment. Proper alignment is critical to maximize the life of the belted drive.

V-Belt Sheaves[edit | edit source]

Dodge v-drive sheaves are manufactured to ISO 9002 quality standards with precision machining that meets or exceeds joint RMA/MPTA industry standards for smooth operation and extended belt life. This design provides low economical costs per horsepower transmitted due to shock load and vibration isolation, creating clean, quiet operation.

V-Belts[edit | edit source]

V-belts allow for compact, lighter-weight drives and feature a high-strength tension member for rated power with minimum stretch. Their molded cog construction accommodates extended belt lengths. S-L classic, classic cog, polyband, and wedge v-belts are also available.

Synchronous Sprockets and Belts[edit | edit source]

Synchronous sprockets improve drives with a curvilinear timing belt. A reinforced belt wraps around and engages a motor-driven sprocket or pulley to transmit translational or rotational motion.

Roller Chain Sprockets[edit | edit source]

Roller chain sprockets reliably handle high-shock loads and deliver large amounts of torque. For ease of installation and removal, Dodge offers roller chain sprockets featuring Taper-Lock bushings. Dodge also offers Torque-Tamer clutches, an overload protection device for roller chain drives that protects the system’s driven equipment.

Motor Bases[edit | edit source]

Motor bases are made of steel, which offers a base of rugged design while being compact and smooth in appearance. Bases are designed to provide adequate travel and are fully adjustable by the use of a single adjusting screw and the elongated mounting holes in the base plate.