Addax

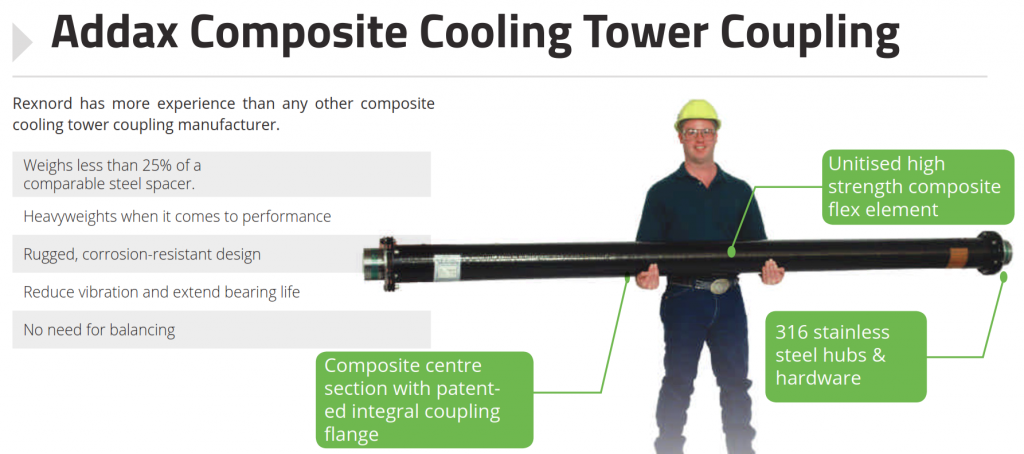

As the first to introduce advanced composite couplings to the cooling tower industry in 1987, Rexnord Addax is recognized as the benchmark in the industry. The lightweight, advanced composite material design increases critical speed, reduces vibration, and extends bearing life compared to alternative all-steel couplings. Rexnord Addax delivers best-in-class performance and lowest total cost of ownership.

Rexnord is a pioneer in design and manufacture of Cooling Tower Couplings for over a century. Rexnord offers Addax® and Thomas® products for Cooling Tower Coupling applications. Floating Shaft Cooling Tower Couplings are used to connect units which are relatively far apart. Such arrangements are particularly suited to transmit power into areas where moisture, dust or corrosive conditions would adversely affect the driving machinery.

Rexnord Cooling Tower Composite Couplings are designed and manufactured specifically for Cooling Tower applications. Performance ratings and materials of construction are in accordance with the Cooling Tower (CT) Institute Standards and specifications.

Rexnord Cooling Tower Couplings are also offered in various options for materials of construction like Zinc-plated or All Stainless Steel. Thomas TSN-CT and SN couplings may be applied with a 1.5 service factor. Composite Floating Shaft Colling Tower Couplings can also be utilized to provide lighter weight, longer spans or higher speeds than can be achieved with steel tubes.

Rexnord Addax CT Disc Couplings[edit | edit source]

Lightweight, floating shaft spacer coupling specifically designed for the harsh rigors of cooling tower applications.

- Configured-to-order based on application requirements

- Custom spacer lengths up to 275 inches (7,000 mm)

- Continuous torque ratings up to 36,200 lb-in (4,090 Nm)

- Shaft diameters up to 12.75 inches and bore capacity up to 5.06 inches

- Dynamically balanced to meet ISO 1940 G6.3 requirements as standard

What makes Addax different than the rest?[edit | edit source]

Proven & Trusted Performance[edit | edit source]

With over 50,000 couplings installed across the world, Rexnord Addax is the most specified coupling globally in the cooling tower industry. Customers continually select Addax Composite Couplings when dependable performance is a must.

Extended System Life[edit | edit source]

Low weight design reduces coupling inertia and overhung bearing loads, resulting in lower vibration and extended service life of connected components.

Rapid Installation & Maintenance[edit | edit source]

Superior design and high misalignment capability enable simplified installation process and ultra-fast replacement of wearable components. Low coupling weight eliminates need for special lifting equipment.

Low Total Cost of Ownership[edit | edit source]

The superior performance and reliability of Addax Composite Couplings along with Rexnord’s unmatched service and quick turnaround capability, combine to deliver the coupling solution with lowest Total Cost of Ownership.

Why choose a Rexnord ® Addax ® Composite Cooling Tower over the alternatives?[edit | edit source]

| Features | Functions | Benefits |

|---|---|---|

| Low Weight | Reduced Mass

Reduce Bearing Loads Reduce Inertia |

Simplified Installation

Increase Bearing Life Reduce Vibration |

| Corrosion Resistance | Resist Chemical Attack | Extend Service Life

Reduce Maintenance Increase Safety Low Cost of Ownership |

| Low Coefficient of

Thermal Expansion |

Dimensional Stability | Reduce Vibration

Reduce Stresses Increase Operating Range |

| Continuous Fiber

Composite Spacer Flange |

Infinite Fatigue Life | Low Cost of Ownership |

| Unitized Flex

Element |

Eliminate Fretting

Infinite Fatigue Life Simplified Installation |

Low Cost of Ownership

Longer Service Life Reduced Maintenance Increased Safety |

| High Misalignment

Capacity |

Reduced Equipment Stress

Increase Life |

Easier Installation

Reduced Ownership Costs |

| High Strength to

Weight Ratio |

Increase Stiffness

Higher Critical Speed |

Eliminate Harmonics

Eliminate Steady Bearings |