Timken Fafnir Ball Bearing Housed Units

Lock in Productivity. Operate Cleaner.

Safeguard system performance and reduce costly wear and tear with the superior contamination protection. Multiple sealing and locking solutions, including eccentric and set screw, provide support for demanding applications. Set screw solutions feature Shaft Guard Technology which eliminates shaft damage from screws.

| Set Screw Locking Collar | Eccentric Locking Collar | Concentric Locking Collar |

|---|---|---|

| Setscrew locking mechanism is easy to install and

well-suited for reversing applications and normal loads. |

The self-locking collar eliminates the need for

locknuts, washers, shoulders, sleeves and adapters. |

These housed units are selected where setscrew

locking is preferred, but inner- ring stress and/or distortion are of major concern. |

|

|

|

Set Screw Locking Collar

1) Y Series

The GY-KRRB series of relubricatable and non-relubricatable bearings offer a full-width inner ring with specially designed setscrews to lock on shafting. The series also features a positive-contact, land-riding R-seal to protect against harmful contaminants and retain lubricant.

Full-width inner ring bearings are ideal where maximum shaft-surface contact is needed for added stability. For shaft protection, the GY-KRRB insert is equipped with shaft-guarding technology.

Design Attributes

- Full-width insert and a three-piece, fiber-imbedded R-seal.

- Setscrew locking mechanism is easy to install and well-suited for reversing applications and normal loads.

Applications

- Construction

- Conveyors

- Food and beverage

- General industrial equipment

- Packaging

2) S Series

The GYA-RRB series of relubricatable and non-relubricatable bearings offer an extended inner ring with specially designed setscrews to lock on shafting. The series also features a positive-contact, land-riding R-seal to protect against harmful contaminants and retain lubricant. Extended inner-ring bearings are used where space is at a premium and load overturn is not a problem.

Design Attributes

- Ideal for applications where space is at a minimum.

- Three-piece Buna-N contact seal with inner and outer shrouds to protect sealing and prevent seal-lip inversion.

- Setscrew locking mechanism is a good fit for reversing applications.

Applications

- Conveyors

- General industrial equipment

- Packaging

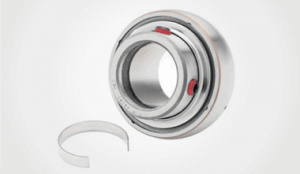

3) Shaft Guarding Technology

This Timken innovation prolongs shaft life while allowing easy installation and removal of a standard setscrew unit. Its technology minimizes shaft damage by protecting shafts from gouging, raised metal and fretting corrosion. These insert bearings are found where production uptime is critical and shaft replacement is expensive.

Design Attributes

- Design includes two conventional setscrews that do not dig into shafts in order to maintain grip.

- Setscrews transfer pressure to the shaft through a stainless-steel hardened band, eliminating direct shaft-setscrew contact.

- A groove runs beneath the setscrews in the inner-ring bore to keep this band stationary.

- The extended length of the inner ring also provides additional stability to improve shaft support and reduce bearing misalignment.

Applications

- Industrial equipment: fan and blower, food and beverage, conveyor, printing press, packaging and textiles

- Rubber and plastic

- Agriculture: combines and implements

Eccentric Locking Collar

1) R Series

Patented in 1923, the self-locking collar remains Timken’s most popular locking system to facilitate mounting of wide inner-ring bearings. The self-locking collar eliminates the need for locknuts, washers, shoulders, sleeves and adapters.

With various seal and inner width variations for many agriculture and industrial applications, self-locking collars are the easiest housed unit to install.

The locking collar has a counterbored recess made purposely eccentric to the collar bore. When assembled on the shaft, this eccentric recess engages, or mates, with an eccentric cam end of a bearing’s inner ring. The collar is engaged on the inner cam of the bearing. This assembly grips the shaft tightly with a positive binding action that increases with use. No adjustments of any kind are necessary. The collar setscrew provides supplementary locking.

Design Attributes

- Unit inserts are full width, allowing them to be more tolerant of static misalignment and capable of holding more aggressive seals.

- Three-piece, fiber-embedded R-seal has outboard and inboard caps which provide longer sealing integrity than average. Eccentric locking collar has self-tightening mechanism.

Applications

- Construction Equipment

- Conveyors

- Fans and Blowers

- Food and beverage

- General Industrial Equipment

- HVAC

- Packaging

V Series

Patented in 1923, the self-locking collar remains Timken’s most popular locking system to facilitate mounting of wide inner-ring bearings. The self-locking collar eliminates the need for locknuts, washers, shoulders, sleeves and adapters.

With various seal and inner width variations for many agriculture and industrial applications, self-locking collars are the easiest housed unit to install.

The locking collar has a counterbored recess made purposely eccentric to the collar bore. When assembled on the shaft, this eccentric recess engages, or mates, with an eccentric cam end of a bearing’s inner ring. The collar is engaged on the inner cam of the bearing. This assembly grips the shaft tightly with a positive binding action that increases with use. No adjustments of any kind are necessary. The collar setscrew provides supplementary locking.

Design Attributes

- Unit inserts offer extended width, allowing them to be installed where space might be a constraint.

- Rubber-bonded seal has an outboard shroud to protect the seal.

- Bearing inner ring has a special profile to resist seal-lip inversion.

Applications

- Conveyors

- Packaging

- General industrial equipment

- Fans and blowers

- Construction equipment

- Food and beverage

Concentric Locking Collar

Fafnir Concentric Locking Collar

These housed units are selected where setscrew locking is preferred, but inner- ring stress and/or distortion are of major concern. They are frequently used in limited-space applications and where reversing shaft rotation is encountered.

Design Attributes

Bearings are locked onto the shaft by two set screws, 120 degrees apart, tightened in the collar and passing through drilled holes in the inner ring.

Applications

- Conveyors

- General Industrial Equipment