SEALMASTER

Since 1935, Sealmaster® bearings have been the industry’s preferred bearing product, engineered for “Performance Without Compromise”. Known for its premium mounted ball bearing line and mounted roller bearings, a long history of cutting-edge innovation, and platform advancements have allowed Sealmaster customers around the world to reduce downtime and improve system uptime reliability.

With a broad selection of both stock sizes and custom designs, Sealmaster bearings are available in multiple high performance sealing options for both wet and dry applications. Whether mounted ball, mounted spherical roller, mounted tapered roller, or rod end and spherical bearings, all designs are engineered for both reduced maintenance and extended bearing life. Multiple locking designs are available, such as the Klamploc™ adapter lock and Skwezloc® locking collar, to meet application and design requirements.

More recent innovations, the IP69K-rated PN Gold™ mounted ball and spherical roller bearings, offer corrosion resistant solutions for washdown environments. The Gold Line mounted ball bearings now feature a patented TIME SAVING™ axial groove in the inner ring bore to reduce time spent on bearing changeout and allowing shaft reuse with minimal clean up (saving more than just time).

For more than 90 years, Sealmaster bearings have proven that they are the solution for the toughest applications.

SEALMASTER USRB™ PN GOLD™ MOUNTED SPHERICAL ROLLER BEARINGS

THE FIRST FULLY CORROSION RESISTANT MOUNTED ROLLER BEARING

IP69K certified to protect in high-pressure, high-temperature washdown applications

Sealmaster® PN Gold™ mounted bearings are now rated to certified IP69K specifications and now includes the industry’s first out of box fully corrosion resistant mounted roller bearing.

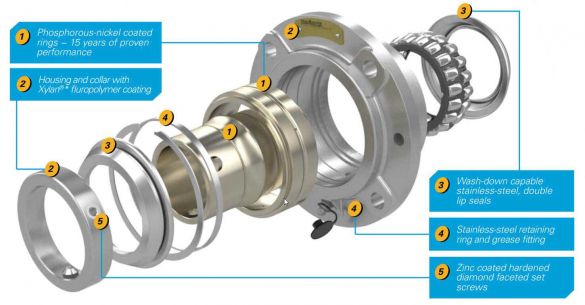

The Sealmaster PN Gold USRB features a phosphorous nickel coated bearing rings, FKM double lip contact seal rides on 300 series stainless seal components and maintains contact as the bearing misaligns providing strong defense against contaminant entry, Flouropolymer coated housing and locking collar and USDA H1 food grade grease.

USRB PN Gold mounted spherical roller bearings are specifically engineered to provide outstanding performance for corrosive wash-down environments, such as food and beverage, pharmaceuticals, and chemical processing.

Housing Coating Performance Chart

| Characteristic | Sealmaster

Corrosion Duty |

Paint | Eletroless Nickel | Teflon®* |

|---|---|---|---|---|

| Acid Resistance | ✔✔✔✔ | ✔ | ✔✔✔ | ✔✔✔✔ |

| Base Resistance | ✔✔✔✔ | ✔ | ✔✔ | ✔✔✔✔ |

| Washdown | ✔✔✔✔ | ✔ | ✔✔ | ✔** |

| General Exposure | ✔✔✔✔ | ✔✔ | ✔✔ | ✔✔✔✔ |

| Non-Stick | ✔✔✔✔ | - | - | ✔✔✔✔ |

| Casting Adhesion | ✔✔✔✔ | ✔✔✔ | ✔✔✔ | ✔ |

| Hardness | ✔✔✔ | ✔✔ | ✔✔✔✔ | ✔ |

| Color | ✔✔✔✔ | ✔ | ✔✔ | ✔✔ |

USRB KLAMPLOC SPHERICAL ADAPTER LOCK

The Sealmaster® unitized spherical roller bearing is now available with the Klamploc™ tapered adapter lock. The Klamploc tapered adapter lock design reduces installation complexities versus standard designs and improves clamping force.

- Basic installation steps clearly marked on collar*.

- Uses common sleeve-lock nut installation process for roller bearings.

- Tighten with common tools such as a hammer & drift, spanner or pipe wrench.

- Reduced length-through-bore – now similar to setscrew collar mount version.

- No parts to remove or bend – simply tighten cap screw to recommended torque after tightening locknut to proper position for final lock down.

NEXT GENERATION SKWEZLOC CONCENTRIC LOCKING COLLAR DESIGN

The Skwezloc® concentric locking collar design first debuted in 1966. In the early 2000’s, more competitive designs with concentric locking collars were introduced.. These designs require Turned, Ground, and Polished (T&P) shaft tolerances. The Sealmaster next generation Skwezloc Concentric Locking Collar has been redesigned to accommodate “Commercial” Turned and Polished (T&P) shaft tolerances with improved lock reliability of T&P shaft tolerances.

Features of the Next Generation Skwezloc® Locking Collar Design include:

- Innovative circumferential groove on the inner ring bore that improves shaft grip.

- Larger cap screw and collar for improved clamping force to the shaft.

- Potential user cost reduction on shafting by specifying “Commercial” tolerances.

- Same simple single screw installation.

- Patented design.