Difference between revisions of "Solid Block – Spherical Roller Bearing"

Bhavinrathod (talk | contribs) |

Bhavinrathod (talk | contribs) |

||

| Line 13: | Line 13: | ||

!Advantage of Solid Block Housing | !Advantage of Solid Block Housing | ||

|- | |- | ||

| − | |90% of split-block bearings fail | + | |90% of split-block bearings fail due to contamination |

| − | due to contamination | + | |14 different sealing options give Blue Brute bearings the highest level of contamination protection |

| − | |14 different sealing options give Blue Brute bearings the | ||

| − | highest level of contamination protection | ||

|- | |- | ||

| − | |Open to environment at | + | |Open to environment at installation |

| − | installation | + | |Completely sealed unit from the factory. Designed to go directly from shelf to the shaft. |

| − | |Completely sealed unit from the factory. Designed to go | ||

| − | directly from shelf to the shaft. | ||

|- | |- | ||

| − | |Need to lubricate until grease | + | |Need to lubricate until grease purges, this is purging contamination from entering the bearing. |

| − | purges, this is purging | + | |Pre-lubricated from the factory, Blue Brute bearings only require minimal re-lubrication intervals. |

| − | + | Excess grease is purged through specially designed seals or relief valves and will never compromise the integrity of the sealing. | |

| − | contamination from entering the | ||

| − | |||

| − | bearing. | ||

| − | |Pre-lubricated from the factory, Blue Brute bearings only | ||

| − | require minimal re-lubrication intervals. Excess grease is | ||

| − | |||

| − | purged through specially designed seals or relief valves | ||

| − | |||

| − | and will never compromise the integrity of the sealing. | ||

|- | |- | ||

|Installation time up to 2 hours | |Installation time up to 2 hours | ||

| − | |Blue Brute bearings require less than 10 minutes | + | |Blue Brute bearings require less than 10 minutes installation time on any size shaft. |

| − | installation time on any size shaft. | ||

|- | |- | ||

|'''Traditional SN Blocks :''' | |'''Traditional SN Blocks :''' | ||

Latest revision as of 19:54, 2 April 2022

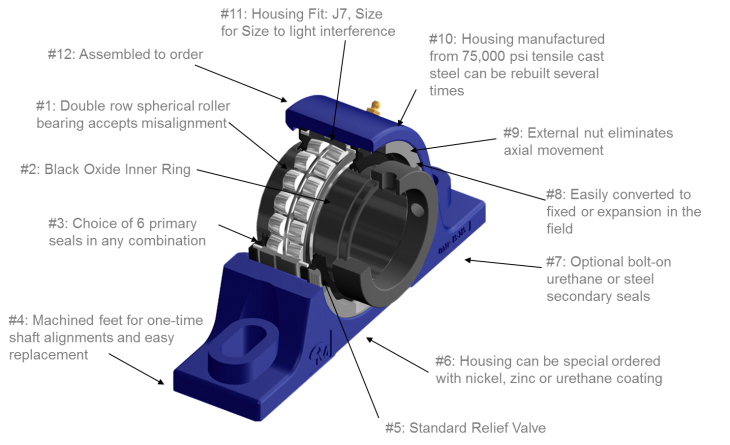

Timken® spherical roller bearing solid-block housed units are designed for the most challenging circumstances. Made with cast-steel housings and Timken high-performance spherical roller bearings, these are the only spherical roller bearing housed units to offer steel solid-block housings as standard. In addition, Timken solid-block housed units can run efficiently on misaligned shafts up to ±0.75 degrees, without a reduction in life expectancy.

With a full line of precision-made locking styles and housings, these solid-block housed units offer protection from contaminants, particularly when used with the many available advanced primary and secondary seal options. Steel auxiliary covers are also available to create another layer of protection from harsh conditions. And, with the Timken bearing selection wizard, finding the right housed unit to fit your application is easy.

Solid Housing Design[edit | edit source]

Key Benefits of SHU over Split Block[edit | edit source]

| Drawback of Split Block Bearing | Advantage of Solid Block Housing |

|---|---|

| 90% of split-block bearings fail due to contamination | 14 different sealing options give Blue Brute bearings the highest level of contamination protection |

| Open to environment at installation | Completely sealed unit from the factory. Designed to go directly from shelf to the shaft. |

| Need to lubricate until grease purges, this is purging contamination from entering the bearing. | Pre-lubricated from the factory, Blue Brute bearings only require minimal re-lubrication intervals.

Excess grease is purged through specially designed seals or relief valves and will never compromise the integrity of the sealing. |

| Installation time up to 2 hours | Blue Brute bearings require less than 10 minutes installation time on any size shaft. |

| Traditional SN Blocks :

Single locking mechanism Limited sealing options Seals on shaft Open to contamination at installation |

Solid Block Housing :

5 minute installations on : QAASN, QASN, QMSN 10 minute installations on : QVSN, QVVSN, TAPN 6 unique locking styles 14 different sealing options |

Industries and Applications[edit | edit source]

- Metal Mills

- Aggregate and Cement

- Mining

- Power Generation

- Sawmills and Other Forest Products Industries

- Pulp and Paper

- Material Conveying

- Commercial and Industrial Building Products

- Sugar MillsAgriculture

- Waste Management and Waste Water Treatment

- Off-Highway and Construction Vehicles

- HVAC, Fans and Blowers

- Cranes, Lifts and Hoists