Difference between revisions of "Timken Fafnir Ball Bearing Housed Units"

Bhavinrathod (talk | contribs) |

Bhavinrathod (talk | contribs) |

||

| (One intermediate revision by the same user not shown) | |||

| Line 149: | Line 149: | ||

* Conveyors | * Conveyors | ||

* General Industrial Equipment | * General Industrial Equipment | ||

| + | |||

| + | == Special Purpose == | ||

| + | Survivor Series housed units excel in highly corrosive environments. | ||

| + | [[File:Survivor.jpg|alt=Survivor|right|frameless|Survivor]] | ||

| + | |||

| + | === 1) Survivor PT Series === | ||

| + | With a polymer housing that is more durable than nylon or coatings, the Survivor PT Series provides lasting protection with high-load capacity. Integral anti-corrosion properties cannot scrape or flake off during use. The polymer resists a broad range of acids and alkalis, as well as steam and continuous temperature up to 120 degrees Celsius (250 degrees Fahrenheit) (brief exposure up to 160 degrees Celsius (320 degrees Fahrenheit)). | ||

| + | |||

| + | === 2) Survivor NT Series === | ||

| + | These units feature an electro less, nickel-plated housing and a corrosion-resistant bearing insert with a choice of locking systems. | ||

| + | |||

| + | === 3) PS Series === | ||

| + | The PS Series offers polymer housing and a 300-series stainless-steel insert to provide the highest possible corrosion resistance. | ||

| + | |||

| + | ==== Design Attributes ==== | ||

| + | |||

| + | * Proprietary thin-dense chrome (TDC) coating is applied to all NT/PT bearing inserts for superior corrosion protection. | ||

| + | * Coating is designed not to crack or peel under known application conditions. | ||

| + | * All Survivor units are FDA/USDA-compliant for incidental contacts. | ||

| + | * Bearings are installed in housings that use engineered torque fits. | ||

| + | * Channels grease to flush through the bearing rather than between the bearing OD and housing. | ||

| + | * Stainless balls, set screws and collars are included (where applicable). | ||

| + | |||

| + | === Applications === | ||

| + | |||

| + | * Food and beverage | ||

| + | * Waste water | ||

| + | * Car washes | ||

| + | * Highway salt and sand | ||

| + | * Chemical and rubber | ||

| + | * Pharmaceutical | ||

| + | * Maritime | ||

| + | * Paper mills | ||

| + | * Material handling | ||

| + | [[File:Cartridge.jpg|alt=Cartridge|right|frameless|Cartridge]] | ||

| + | |||

| + | === 4) Cartridges === | ||

| + | Our cartridges are available in metallic or rubber. The bearing inserts have grade 10 balls and super-finished ball paths to support proper lube film and reduce noise. | ||

| + | |||

| + | ==== Metallic Design Attributes ==== | ||

| + | |||

| + | * Mounts in straight bore housings. | ||

| + | * Comes complete with wide inner-ring bearing insert and three-piece “R” seal. | ||

| + | |||

| + | ==== Conductive Rubber Design Attributes ==== | ||

| + | |||

| + | * Offers straight, beveled or special profiled outer diameter. | ||

| + | * Comes complete with extended inner ring bearing insert. | ||

| + | * Very quiet and dampens vibration. | ||

| + | |||

| + | ==== Applications ==== | ||

| + | |||

| + | * Heating and air-conditioning | ||

| + | * Ventilating equipment | ||

| + | * Conveyor systems | ||

| + | * General industrial equipment | ||

| + | [[File:Idler Pulley.jpg|alt=Idler Pulley|right|frameless|Idler Pulley]] | ||

| + | |||

| + | === 5) Idler Pulleys === | ||

| + | Timken’s integrated, pressed-steel idler pulleys combine a precision ball bearing with rubber seals to create a self-contained unit. | ||

| + | |||

| + | ==== Design Attributes ==== | ||

| + | |||

| + | * A single-row radial ball bearing with an inner ring extends on both sides to provide clearance for abutting parts and obtain greater shaft support. | ||

| + | * Contact-type rubber seals assure positive retention for lubricant and full protection against dirt, dust and foreign matter. | ||

| + | * All units are non-relubricatable. | ||

| + | |||

| + | ==== Applications ==== | ||

| + | |||

| + | * Agriculture | ||

| + | * Forestry | ||

| + | |||

| + | ==== Special Features Available ==== | ||

| + | |||

| + | * Smoothly rolled-over edges to eliminate chafing and scuffing. | ||

| + | * Weep holes on the rivet circle to supply water drainage while they are being mounted horizontally. | ||

| + | |||

| + | Designs available: V-belts, backs of V-belts. Both are made for A, B, C and D-section belts. | ||

| + | |||

| + | Housing types available: V, flat and chain. | ||

| + | [[File:DiskHarrow.jpg|alt=DiskHarrow|right|frameless|DiskHarrow]] | ||

| + | |||

| + | === 6) Disk Harrow Units === | ||

| + | Timken’s disk harrow units provide protection against dirt in agricultural applications. | ||

| + | |||

| + | ==== Design Attributes ==== | ||

| + | |||

| + | * Patented design uses Timken’s cutting-edge sealing technology. | ||

| + | * Molded, one-piece rubber integrated inner seal and flexible composite retainer work together to reject dirt and moisture. | ||

| + | * Rugged construction and high-quality ball bearings are known for maximizing life in wide-spread industrial applications. | ||

| + | * Bearings are placed in stamped, heavy-gage housings to offer close clearance to inner-ring shrouds. | ||

| + | |||

| + | ==== Applications ==== | ||

| + | |||

| + | * Agriculture (field preparation) | ||

| + | * Industrial equipment | ||

| + | [[File:SafetyCaps.jpg|alt=SafetyCaps|right|frameless|SafetyCaps]] | ||

| + | |||

| + | === 7) Fafnir Safety End Caps === | ||

| + | Easy-to-install safety end caps protect exposed rotating shafts, reducing hazards around many types of equipment. The patent-pending design meets all applicable OSHA requirements. | ||

| + | |||

| + | The new Fafnir® safety product line consists of a mounting ring and snap-on cover, both molded in a durable, bright yellow polymer. The end cap snaps into the adhesive-backed ring that adheres to the outboard face of most flanged bearing housings. The secure, 360-degree fit makes for a rugged unit that also provides basic protection from contaminants and washdown. | ||

| + | |||

| + | Factory retrofits are a snap with everything provided in a handy kit. The cost-effective end covers are simple to install on Timken and most other flanged units. Current sizes range from 20 mm to 50 mm (3⁄4in. to 1-15/16in.) shaft sizes for two or four-bolt flanged cast iron, malleable iron, and other selected housing styles and sizes. | ||

| + | |||

| + | ==== Design Attributes ==== | ||

| + | |||

| + | * Improved safety – convenient means to protect factory workers from contact with rotating stub shafts. | ||

| + | * OSHA requirements – design meets current OSHA regulations mandating safety covers for exposed shafting. | ||

| + | * Easy installation – end cap snaps easily and securely into adhesivebacked mounting ring. | ||

| + | * High visibility – both end cap and mounting ring are molded in bright yellow for optimum visibility and safety. | ||

| + | * Simple retrofit – convenient field installation involves easy attachment of mounting ring to outboard face of a variety of housed units from different manufacturers. | ||

| + | * Flexible use – easy field installation expands application for housed units produced by a variety of manufacturers. | ||

| + | * Cost efficiency – quick and simple field retrofits minimize downtime and avoid replacing existing housed units. | ||

| + | * Durable service – tough polymer components and strong adhesive bond stand up to typical factory usage. | ||

| + | * Contamination protection – end cap with 360° interlocking fit provides basic protection against contamination and washdown. | ||

| + | * Convenient kits – everything needed for installation is provided in a handy kit. | ||

| + | |||

| + | ==== Applications ==== | ||

| + | |||

| + | * Food processing | ||

| + | * Material handling, including conveyors, luggage handling and packaging lines | ||

Latest revision as of 06:12, 2 April 2022

Lock in Productivity. Operate Cleaner.[edit | edit source]

Safeguard system performance and reduce costly wear and tear with the superior contamination protection. Multiple sealing and locking solutions, including eccentric and set screw, provide support for demanding applications. Set screw solutions feature Shaft Guard Technology which eliminates shaft damage from screws.

| Set Screw Locking Collar | Eccentric Locking Collar | Concentric Locking Collar |

|---|---|---|

| Setscrew locking mechanism is easy to install and

well-suited for reversing applications and normal loads. |

The self-locking collar eliminates the need for

locknuts, washers, shoulders, sleeves and adapters. |

These housed units are selected where setscrew

locking is preferred, but inner- ring stress and/or distortion are of major concern. |

|

|

|

Set Screw Locking Collar[edit | edit source]

1) Y Series[edit | edit source]

The GY-KRRB series of relubricatable and non-relubricatable bearings offer a full-width inner ring with specially designed setscrews to lock on shafting. The series also features a positive-contact, land-riding R-seal to protect against harmful contaminants and retain lubricant.

Full-width inner ring bearings are ideal where maximum shaft-surface contact is needed for added stability. For shaft protection, the GY-KRRB insert is equipped with shaft-guarding technology.

Design Attributes[edit | edit source]

- Full-width insert and a three-piece, fiber-imbedded R-seal.

- Setscrew locking mechanism is easy to install and well-suited for reversing applications and normal loads.

Applications[edit | edit source]

- Construction

- Conveyors

- Food and beverage

- General industrial equipment

- Packaging

2) S Series[edit | edit source]

The GYA-RRB series of relubricatable and non-relubricatable bearings offer an extended inner ring with specially designed setscrews to lock on shafting. The series also features a positive-contact, land-riding R-seal to protect against harmful contaminants and retain lubricant. Extended inner-ring bearings are used where space is at a premium and load overturn is not a problem.

Design Attributes[edit | edit source]

- Ideal for applications where space is at a minimum.

- Three-piece Buna-N contact seal with inner and outer shrouds to protect sealing and prevent seal-lip inversion.

- Setscrew locking mechanism is a good fit for reversing applications.

Applications[edit | edit source]

- Conveyors

- General industrial equipment

- Packaging

3) Shaft Guarding Technology[edit | edit source]

This Timken innovation prolongs shaft life while allowing easy installation and removal of a standard setscrew unit. Its technology minimizes shaft damage by protecting shafts from gouging, raised metal and fretting corrosion. These insert bearings are found where production uptime is critical and shaft replacement is expensive.

Design Attributes[edit | edit source]

- Design includes two conventional setscrews that do not dig into shafts in order to maintain grip.

- Setscrews transfer pressure to the shaft through a stainless-steel hardened band, eliminating direct shaft-setscrew contact.

- A groove runs beneath the setscrews in the inner-ring bore to keep this band stationary.

- The extended length of the inner ring also provides additional stability to improve shaft support and reduce bearing misalignment.

Applications[edit | edit source]

- Industrial equipment: fan and blower, food and beverage, conveyor, printing press, packaging and textiles

- Rubber and plastic

- Agriculture: combines and implements

Eccentric Locking Collar[edit | edit source]

1) R Series[edit | edit source]

Patented in 1923, the self-locking collar remains Timken’s most popular locking system to facilitate mounting of wide inner-ring bearings. The self-locking collar eliminates the need for locknuts, washers, shoulders, sleeves and adapters.

With various seal and inner width variations for many agriculture and industrial applications, self-locking collars are the easiest housed unit to install.

The locking collar has a counterbored recess made purposely eccentric to the collar bore. When assembled on the shaft, this eccentric recess engages, or mates, with an eccentric cam end of a bearing’s inner ring. The collar is engaged on the inner cam of the bearing. This assembly grips the shaft tightly with a positive binding action that increases with use. No adjustments of any kind are necessary. The collar setscrew provides supplementary locking.

Design Attributes[edit | edit source]

- Unit inserts are full width, allowing them to be more tolerant of static misalignment and capable of holding more aggressive seals.

- Three-piece, fiber-embedded R-seal has outboard and inboard caps which provide longer sealing integrity than average. Eccentric locking collar has self-tightening mechanism.

Applications[edit | edit source]

- Construction Equipment

- Conveyors

- Fans and Blowers

- Food and beverage

- General Industrial Equipment

- HVAC

- Packaging

V Series[edit | edit source]

Patented in 1923, the self-locking collar remains Timken’s most popular locking system to facilitate mounting of wide inner-ring bearings. The self-locking collar eliminates the need for locknuts, washers, shoulders, sleeves and adapters.

With various seal and inner width variations for many agriculture and industrial applications, self-locking collars are the easiest housed unit to install.

The locking collar has a counterbored recess made purposely eccentric to the collar bore. When assembled on the shaft, this eccentric recess engages, or mates, with an eccentric cam end of a bearing’s inner ring. The collar is engaged on the inner cam of the bearing. This assembly grips the shaft tightly with a positive binding action that increases with use. No adjustments of any kind are necessary. The collar setscrew provides supplementary locking.

Design Attributes[edit | edit source]

- Unit inserts offer extended width, allowing them to be installed where space might be a constraint.

- Rubber-bonded seal has an outboard shroud to protect the seal.

- Bearing inner ring has a special profile to resist seal-lip inversion.

Applications[edit | edit source]

- Conveyors

- Packaging

- General industrial equipment

- Fans and blowers

- Construction equipment

- Food and beverage

Concentric Locking Collar[edit | edit source]

Fafnir Concentric Locking Collar[edit | edit source]

These housed units are selected where setscrew locking is preferred, but inner- ring stress and/or distortion are of major concern. They are frequently used in limited-space applications and where reversing shaft rotation is encountered.

Design Attributes[edit | edit source]

Bearings are locked onto the shaft by two set screws, 120 degrees apart, tightened in the collar and passing through drilled holes in the inner ring.

Applications[edit | edit source]

- Conveyors

- General Industrial Equipment

Special Purpose[edit | edit source]

Survivor Series housed units excel in highly corrosive environments.

1) Survivor PT Series[edit | edit source]

With a polymer housing that is more durable than nylon or coatings, the Survivor PT Series provides lasting protection with high-load capacity. Integral anti-corrosion properties cannot scrape or flake off during use. The polymer resists a broad range of acids and alkalis, as well as steam and continuous temperature up to 120 degrees Celsius (250 degrees Fahrenheit) (brief exposure up to 160 degrees Celsius (320 degrees Fahrenheit)).

2) Survivor NT Series[edit | edit source]

These units feature an electro less, nickel-plated housing and a corrosion-resistant bearing insert with a choice of locking systems.

3) PS Series[edit | edit source]

The PS Series offers polymer housing and a 300-series stainless-steel insert to provide the highest possible corrosion resistance.

Design Attributes[edit | edit source]

- Proprietary thin-dense chrome (TDC) coating is applied to all NT/PT bearing inserts for superior corrosion protection.

- Coating is designed not to crack or peel under known application conditions.

- All Survivor units are FDA/USDA-compliant for incidental contacts.

- Bearings are installed in housings that use engineered torque fits.

- Channels grease to flush through the bearing rather than between the bearing OD and housing.

- Stainless balls, set screws and collars are included (where applicable).

Applications[edit | edit source]

- Food and beverage

- Waste water

- Car washes

- Highway salt and sand

- Chemical and rubber

- Pharmaceutical

- Maritime

- Paper mills

- Material handling

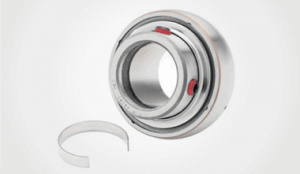

4) Cartridges[edit | edit source]

Our cartridges are available in metallic or rubber. The bearing inserts have grade 10 balls and super-finished ball paths to support proper lube film and reduce noise.

Metallic Design Attributes[edit | edit source]

- Mounts in straight bore housings.

- Comes complete with wide inner-ring bearing insert and three-piece “R” seal.

Conductive Rubber Design Attributes[edit | edit source]

- Offers straight, beveled or special profiled outer diameter.

- Comes complete with extended inner ring bearing insert.

- Very quiet and dampens vibration.

Applications[edit | edit source]

- Heating and air-conditioning

- Ventilating equipment

- Conveyor systems

- General industrial equipment

5) Idler Pulleys[edit | edit source]

Timken’s integrated, pressed-steel idler pulleys combine a precision ball bearing with rubber seals to create a self-contained unit.

Design Attributes[edit | edit source]

- A single-row radial ball bearing with an inner ring extends on both sides to provide clearance for abutting parts and obtain greater shaft support.

- Contact-type rubber seals assure positive retention for lubricant and full protection against dirt, dust and foreign matter.

- All units are non-relubricatable.

Applications[edit | edit source]

- Agriculture

- Forestry

Special Features Available[edit | edit source]

- Smoothly rolled-over edges to eliminate chafing and scuffing.

- Weep holes on the rivet circle to supply water drainage while they are being mounted horizontally.

Designs available: V-belts, backs of V-belts. Both are made for A, B, C and D-section belts.

Housing types available: V, flat and chain.

6) Disk Harrow Units[edit | edit source]

Timken’s disk harrow units provide protection against dirt in agricultural applications.

Design Attributes[edit | edit source]

- Patented design uses Timken’s cutting-edge sealing technology.

- Molded, one-piece rubber integrated inner seal and flexible composite retainer work together to reject dirt and moisture.

- Rugged construction and high-quality ball bearings are known for maximizing life in wide-spread industrial applications.

- Bearings are placed in stamped, heavy-gage housings to offer close clearance to inner-ring shrouds.

Applications[edit | edit source]

- Agriculture (field preparation)

- Industrial equipment

7) Fafnir Safety End Caps[edit | edit source]

Easy-to-install safety end caps protect exposed rotating shafts, reducing hazards around many types of equipment. The patent-pending design meets all applicable OSHA requirements.

The new Fafnir® safety product line consists of a mounting ring and snap-on cover, both molded in a durable, bright yellow polymer. The end cap snaps into the adhesive-backed ring that adheres to the outboard face of most flanged bearing housings. The secure, 360-degree fit makes for a rugged unit that also provides basic protection from contaminants and washdown.

Factory retrofits are a snap with everything provided in a handy kit. The cost-effective end covers are simple to install on Timken and most other flanged units. Current sizes range from 20 mm to 50 mm (3⁄4in. to 1-15/16in.) shaft sizes for two or four-bolt flanged cast iron, malleable iron, and other selected housing styles and sizes.

Design Attributes[edit | edit source]

- Improved safety – convenient means to protect factory workers from contact with rotating stub shafts.

- OSHA requirements – design meets current OSHA regulations mandating safety covers for exposed shafting.

- Easy installation – end cap snaps easily and securely into adhesivebacked mounting ring.

- High visibility – both end cap and mounting ring are molded in bright yellow for optimum visibility and safety.

- Simple retrofit – convenient field installation involves easy attachment of mounting ring to outboard face of a variety of housed units from different manufacturers.

- Flexible use – easy field installation expands application for housed units produced by a variety of manufacturers.

- Cost efficiency – quick and simple field retrofits minimize downtime and avoid replacing existing housed units.

- Durable service – tough polymer components and strong adhesive bond stand up to typical factory usage.

- Contamination protection – end cap with 360° interlocking fit provides basic protection against contamination and washdown.

- Convenient kits – everything needed for installation is provided in a handy kit.

Applications[edit | edit source]

- Food processing

- Material handling, including conveyors, luggage handling and packaging lines