Difference between revisions of "Preparation & Mounting of Gamet Bearings"

| (One intermediate revision by the same user not shown) | |||

| Line 1: | Line 1: | ||

| + | ''<small>(Go back to [http://catalog.jinharsh.co.in/index.php/Gamet_Bearings Gamet Bearings])</small>'' | ||

| + | |||

It is recommended that drawings and instructions are studied to determine the correct order of assembly. All necessary parts, tools and equipment should be available before commencing. | It is recommended that drawings and instructions are studied to determine the correct order of assembly. All necessary parts, tools and equipment should be available before commencing. | ||

| − | + | [[File:Typical Lathe Spindle Assembly Gamet Bearings.png|alt=Illustration of Typical Lathe Spindle Assembly with Gamet Bearings|thumb|500x500px|Typical Lathe Spindle Assembly Gamet Bearings]] | |

Each component of the spindle arrangement (housing, shaft etc.) must be carefully cleaned and checked for burrs. Dimensional and form accuracy of all components in contact with the bearings should be checked as optimum bearing performance can only be achieved if the prescribed tolerances are adhered to. | Each component of the spindle arrangement (housing, shaft etc.) must be carefully cleaned and checked for burrs. Dimensional and form accuracy of all components in contact with the bearings should be checked as optimum bearing performance can only be achieved if the prescribed tolerances are adhered to. | ||

Latest revision as of 14:17, 23 April 2021

(Go back to Gamet Bearings)

It is recommended that drawings and instructions are studied to determine the correct order of assembly. All necessary parts, tools and equipment should be available before commencing.

Each component of the spindle arrangement (housing, shaft etc.) must be carefully cleaned and checked for burrs. Dimensional and form accuracy of all components in contact with the bearings should be checked as optimum bearing performance can only be achieved if the prescribed tolerances are adhered to.

Bearings should remain in the original packaging for as long as possible prior to fitting to prevent the risk of contamination. Whenever possible, bearings should be mounted onto the shaft in vertical position. It is very important that the correct method of mounting is chosen and that suitable equipment is used.

The inner races (cones) of the bearings must be pre-heated to expand sufficiently to assist mounting on shaft. Never attempt to fit cold as the amount of interference between cones and shaft will prevent sliding and any direct blows will cause damage to rolling elements and raceways. Heating can be achieved using induction heaters, ideal for grease lubricated bearings, or oil baths suitable for oil lubricated bearings.

Under no circumstances should a pre-greased bearing be heated by submersing in oil as contamination of grease will occur. The temperature required to sufficiently expand cones to allow reasonable mounting time varies depending upon size and section, but 70°C will suffice for the majority of applications. Care must be taken when locking bearings to ensure all rolling elements are seated properly, this is achieved by rotating at periodic intervals during locking.

Lubrication[edit | edit source]

Bearings must be correctly lubricated to reduce friction between the rolling elements and raceways. Lubrication will minimise wear and protect bearing surfaces against corrosion. The choice of a suitable lubricant and method of lubrication is very important and depends upon the operating conditions (temperature, range, speeds, loads, environment). A wide variety of greases and oils is available offering solutions for all applications.

Oil[edit | edit source]

Oil lubrication is normally used where higher operating speeds are required as this offers more efficient heat dissipation. The selection of a suitable viscosity grade is important to optimise the life and performance of bearings and adjacent components. Filtration is strongly recommended as contaminated oil will have an adverse effect on bearing life and performance. Regular inspection of oil and filters is advised and changes made when necessary. Catalogue speed ratings are based on the use of oil lubrication.

Grease[edit | edit source]

Grease lubrication offers a simplified and cost effective option as the lubricant is more easily retained within the bearing. It also eliminates the need for complicated and costly lubrication delivery and drainage systems. Sealing of the bearings is important to eliminate the possibility of contaminant ingress and to retain the grease within the bearing structure. Bearing speed ratings may reduce with grease lubrication. If you plan to use greased bearings, advice on maximum speeds can be obtained from Gamet’s engineering department. Gamet Bearings offers a service of supplying bearings pre- greased to suit your requirements.

Running-in[edit | edit source]

After installation bearings require a running-in phase to condition and match mating surfaces, this will ensure optimum performance. This is more critical when using grease lubrication as sufficient time is required to disperse and evenly distribute the lubricant within the bearing. If this is neglected, temperatures can rise rapidly causing localised overheating and lubricant break-down which can lead to premature bearing failure or inferior spindle performance.

Specials[edit | edit source]

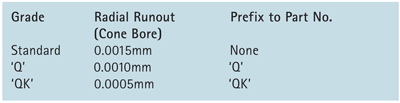

Gamet Bearings are available in the following Precision Grades:

Gamet Bearings SpecialsHigher specification grades offer improved radial run-outs and component roundness. Gamet Bearings also offer a comprehensive service for the design and manufacture of other Tapered Roller Bearings to suit specific requirements. We will be pleased to offer our experience and technical expertise in assisting you to achieve the best possible results and maximise cost effectiveness, for all non-standard applications.

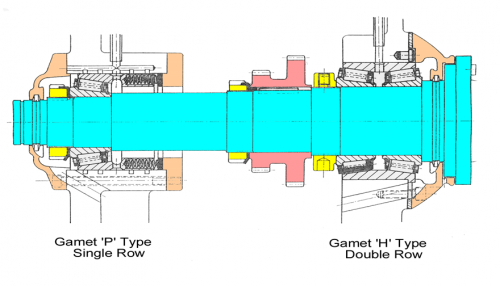

Component parts of Gamet Tapered Roller Bearing[edit | edit source]

Gamet bearings consist of four basic components – the inner race (cone), the outer race (cup), tapered rollers and cage. The cone, rollers and cage form an assembly which is separable from the cup.

Cup - Outer Race.

Cone - Inner Race.

Rollers - Hollow, unique to Gamet.

Cage - Aluminium, one piece.

Spacer - Double row bearings only.

Circlip - Retains cage & roller ass’y.

Principles of Gamet Tapered Roller Bearings

The geometry of tapered roller bearings provides certain unique features: most importantly, the long line contact between roller and race gives high load carrying capacity and high bearing stiffness. The ‘on apex’ design ensures a true rolling motion of the rollers on the raceways, at every point along the roller body. See Fig 1. In addition, the tapered construction allows the bearing to carry combinations of radial and thrust load. The small seating force (x) produced at the rib aligns the rollers to prevent skewing. See Fig 2.

Other specific features of Gamet tapered roller bearings include:-[edit | edit source]

Precision – Gamet bearings are manufactured only in a high precision class.

Hollow Rollers – This assists the flow of lubricant through the bearing to provide cooling.

Roller Roundness and Calibration – A true roundness of rollers ensures equal load sharing within the bearing and contributes significantly to the overall precision of the bearings. Gamet Rollers are ground between centres to achieve near perfect roundness. Rollers are then calibrated precisely into matched sets.

Bearing Cage – The cage has a low coeficient of friction. It is guided on the inner race to provide radial stability and is designed to pass sufficient oil across the races to maintain lubrication, the remainder being diverted through the centre of the roller. Depending on rotational speed, grease lubrication may be used as an alternative to oil.