Difference between revisions of "Timken Tapered Roller Bearings"

Bhavinrathod (talk | contribs) (→Single) |

|||

| (10 intermediate revisions by one other user not shown) | |||

| Line 1: | Line 1: | ||

| − | = Inch Single Row = | + | = Single Row Bearing = |

| + | |||

| + | === Inch Single Row === | ||

Single-row tapered roller bearings are the most basic and widely used, consisting of a cone assembly and a cup. Timken patented the first in 1898 and today offers the world's widest variety in inch and metric sizes. | Single-row tapered roller bearings are the most basic and widely used, consisting of a cone assembly and a cup. Timken patented the first in 1898 and today offers the world's widest variety in inch and metric sizes. | ||

{| class="wikitable" | {| class="wikitable" | ||

| − | |||

| − | |||

|- | |- | ||

![[File:TS.jpg|frameless]] | ![[File:TS.jpg|frameless]] | ||

TS | TS | ||

| − | |This is the most basic and most widely used type of tapered roller bearing. It consists of two main separable parts: the inner race assembly and the outer race. It is typically mounted in opposing pairs on a shaft. | + | |This is the most basic and most widely used type of tapered roller bearing. It consists of two main separable parts: the inner race assembly and the outer race. It is typically mounted in opposing pairs on a shaft.<br /> |

| − | + | '''Size Range :''' | |

| − | |||

| − | |||

| − | |||

| − | '''Size Range :''' | ||

ID 7.937 to 1562.100 mm (0.31225 to 61.5000 in.) | ID 7.937 to 1562.100 mm (0.31225 to 61.5000 in.) | ||

OD 31.991 to 1806.575 mm (1.2595 to 71.1250 in.) | OD 31.991 to 1806.575 mm (1.2595 to 71.1250 in.) | ||

| − | |||

| − | |||

'''Design Attributes :''' | '''Design Attributes :''' | ||

| Line 27: | Line 21: | ||

- Pin type cages also available | - Pin type cages also available | ||

| − | |||

| − | |||

'''Applications :''' | '''Applications :''' | ||

| − | - Vehicle front wheels | + | - Vehicle front wheels, Differential and pinion configurations, Conveyor rolls, Machine tool spindles, Trailer wheels |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|- | |- | ||

![[File:TSF (Flanged Cup).jpg|frameless]] | ![[File:TSF (Flanged Cup).jpg|frameless]] | ||

| Line 52: | Line 36: | ||

OD 31.991 mm to 1435.100 mm (1.2595 in. to 56.5000 in.) | OD 31.991 mm to 1435.100 mm (1.2595 in. to 56.5000 in.) | ||

| − | |||

'''Design Attributes :''' | '''Design Attributes :''' | ||

| Line 61: | Line 44: | ||

- Reduced machining costs. | - Reduced machining costs. | ||

| − | |||

'''Applications :''' | '''Applications :''' | ||

| − | - Machine tool spindles | + | - Machine tool spindles, Gear reduction units, Automotive transaxles ,Transmissions |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|- | |- | ||

![[File:TSU (Unit-Bearing).jpg|frameless]] | ![[File:TSU (Unit-Bearing).jpg|frameless]] | ||

| Line 83: | Line 59: | ||

OD 58.000 mm to 80.000 mm (2.2835 in. to 3.1496 in.) | OD 58.000 mm to 80.000 mm (2.2835 in. to 3.1496 in.) | ||

| − | |||

'''Design Attributes :''' | '''Design Attributes :''' | ||

| Line 90: | Line 65: | ||

- Manages heavy radial loads and thrust loads in either direction. | - Manages heavy radial loads and thrust loads in either direction. | ||

| − | |||

'''Applications :''' | '''Applications :''' | ||

| − | - Automotive rear wheels | + | - Automotive rear wheels, Transmissions, Gear reduction units, Industrial equipment |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|- | |- | ||

![[File:TSL (with Duo Face-Plus Seals).jpg|center|frameless]]TSL (with Duo Face-Plus Seals) | ![[File:TSL (with Duo Face-Plus Seals).jpg|center|frameless]]TSL (with Duo Face-Plus Seals) | ||

| Line 111: | Line 79: | ||

OD 45.237 mm to 110 mm (1.7810 in. to 4.3307 in.) | OD 45.237 mm to 110 mm (1.7810 in. to 4.3307 in.) | ||

| − | |||

'''Design Attributes :''' | '''Design Attributes :''' | ||

| Line 118: | Line 85: | ||

One seal lip operates in the housing bore while the other seals against the cup face. | One seal lip operates in the housing bore while the other seals against the cup face. | ||

| − | |||

'''Applications :''' | '''Applications :''' | ||

| − | - Moderate- to low-speed automotive and industrial applications | + | - Moderate- to low-speed automotive and industrial applications, Aircraft wheels, Farm implement wheels, Idler rollers, Side-delivery hay rakes |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|- | |- | ||

![[File:TSRB (Snap-ring cup).jpg|frameless]] | ![[File:TSRB (Snap-ring cup).jpg|frameless]] | ||

| Line 138: | Line 96: | ||

OD 57.150 mm to 180.975 mm (2.2500 in. to 7.1250 in.) | OD 57.150 mm to 180.975 mm (2.2500 in. to 7.1250 in.) | ||

| − | |||

'''Design Attributes :''' | '''Design Attributes :''' | ||

| Line 145: | Line 102: | ||

- Can be ordered with or without snap ring. | - Can be ordered with or without snap ring. | ||

| − | |||

'''Applications :''' | '''Applications :''' | ||

| − | - Machine tool spindles | + | - Machine tool spindles, Gear reduction units, Automotive transaxles, Transmissions |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

|- | |- | ||

![[File:Fuel Efficient Bearings.jpg|frameless]] | ![[File:Fuel Efficient Bearings.jpg|frameless]] | ||

| Line 169: | Line 119: | ||

-Controlled set-up torque helps you achieve more accurate settings, resulting in the highest axle performance possible. | -Controlled set-up torque helps you achieve more accurate settings, resulting in the highest axle performance possible. | ||

| − | |||

'''Applications :''' | '''Applications :''' | ||

| Line 183: | Line 132: | ||

- As a leader in tapered roller bearing technology, we engineer bearings to outlast and outperform those frequently used on original equipment. | - As a leader in tapered roller bearing technology, we engineer bearings to outlast and outperform those frequently used on original equipment. | ||

| − | |||

'''Design Attributes :''' | '''Design Attributes :''' | ||

| Line 216: | Line 164: | ||

- Streamlined Inventory Management: With a wide range of part numbers, each kit features two Timken® MileMate® matched bearing sets and a precision-machined spacer (five common spacer types available). | - Streamlined Inventory Management: With a wide range of part numbers, each kit features two Timken® MileMate® matched bearing sets and a precision-machined spacer (five common spacer types available). | ||

| − | - More Uptime: MileMate bearings, manufactured with super-clean high-strength alloy steel, precision profiles and enhanced surface finishes, feature high load ratings, and outlast and outperform competitor bearings. | + | - More Uptime: MileMate bearings, manufactured with super-clean high-strength alloy steel, precision profiles and enhanced surface finishes, feature high load ratings, and outlast and outperform competitor bearings. |

| − | + | '''Applications :''' | |

| − | '''Applications :''' | ||

- Commercial vehicles (aftermarket) | - Commercial vehicles (aftermarket) | ||

| Line 245: | Line 192: | ||

- Meets or exceed original equipment manufacturers’ specifications, including specifications for ConMet® PreSet® hubs and Spicer® LMS™ hubs. | - Meets or exceed original equipment manufacturers’ specifications, including specifications for ConMet® PreSet® hubs and Spicer® LMS™ hubs. | ||

| + | |||

| + | '''Applications :''' | ||

| + | |||

| + | - Commercial vehicles (aftermarket) | ||

| + | |} | ||

| + | |||

| + | === Metric Single Row === | ||

| + | The company continues to extend its line of Timken® single row metric tapered roller bearings to respond to customer needs and today offers one of the industry's broadest ranges of metric parts. | ||

| + | {| class="wikitable mw-collapsible mw-collapsed" | ||

| + | |- | ||

| + | ![[File:Metric Single Row.jpg|frameless]] | ||

| + | Metric Single Row | ||

| + | |Known for having the widest range of inch single row tapered roller bearings, Timken also offers a wide range of popular metric single row tapered roller bearings in accordance with ISO 355:2007. Please see the Timken Metric Tapered Roller Bearings catalog below for product tables and part-numbering system information. | ||

| + | |||

| + | |||

| + | '''Design Attributes :''' | ||

| + | |||

| + | - Standard design bearings reflected in the catalog deliver long service life for a wide range of industrial and mobile applications. | ||

| + | |||

| + | - Premium design bearings are available on many part numbers upon request to meet higher performance requirements for the most challenging applications. | ||

| + | |||

| + | - Certain sizes are available with a flanged outer ring, facilitating accurate alignment of housing bores. | ||

| + | |||

| + | - Two single-row metric matched bearing assemblies are also available for applications requiring higher load carrying capacity or where the shaft must be located axially in both directions with a specific axial clearance or preload. | ||

| + | |||

| + | '''Applications :''' | ||

| + | |||

| + | - Gear boxes, pumps and conveyors used in power gen, mining, oil and gas, wind energy, pulp and paper, food and beverage, gear drives, cement and metals applications. | ||

| + | |||

| + | - Drive trains, gear drives, axle centers, wheel ends and transmissions used in construction, mining, rail, automotive and commercial vehicles. | ||

| + | |} | ||

| + | |||

| + | = Double Row Bearing = | ||

| + | |||

| + | === Inch Double Row === | ||

| + | Double- or two-row Timken® tapered roller bearings feature double cups and two single cones. They are available in a variety of configurations for general industrial and automotive applications. | ||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ![[File:TDI (Two-Row Double Inner Race).jpg|center|frameless]]TDI (Two-Row Double Inner Race) | ||

| + | |TDI bearings have a one-piece double inner race and two single outer races and are typically supplied complete with an outer race spacer as a pre-set assembly. The bearing can be used at fixed positions on rotation shaft applications. For rotating housing application it can be used to float on the stationary shaft. TDI bearings are sometimes used on rotating shaft applications where a loose fit is required for ease of removal. | ||

| + | |||

| + | |||

| + | '''Size range :''' | ||

| + | |||

| + | - ID 25.400 mm to 1200.150 mm (1.000 in. to 47.2500 in.) | ||

| + | |||

| + | - OD 30.480 mm to 2460.000 mm (1.2000 in. to 96.8504 in.) | ||

| + | |||

| + | '''Design Attributes :''' | ||

| + | |||

| + | - Double cone and two single cups, with or without a cup spacer. | ||

| + | |||

| + | - Furnished as a matched assembly. | ||

| + | |||

| + | - Cups ground to fit. | ||

| + | |||

| + | '''Applications :''' | ||

| + | |||

| + | - Gear reduction units, Cranes, Calendar rolls, Industrial machinery | ||

| + | |- | ||

| + | ![[File:TDO (Two-Row Double-Outer Race).jpg|center|frameless]]TDO (Two-Row Double-Outer Race) | ||

| + | |The configuration of the TDO provides a wide effective bearing spread, making it ideal for applications in which overturning moments are a significant load component. TDO bearings can be used in fixed positions or allowed to float in the housing bore. | ||

| + | '''Size range :''' | ||

| + | |||

| + | - ID 25.400 mm to 1200.150 mm (1.0000 in. to 47.2500 in.) | ||

| + | |||

| + | - OD 30.480 mm to 2460.000 mm (1.2000 in. to 96.8504 in.) | ||

| + | |||

| + | '''Design Attributes :''' | ||

| + | |||

| + | - Double cup and two single cones, with or without a spacer. | ||

| + | |||

| + | - When spacers are used, bearing is furnished as a preset, matched assembly. | ||

| + | |||

| + | - Cup features groove and lubrication holes in the OD. | ||

| + | |||

| + | - Spacers available with or without lubricant grooves and holes. | ||

| + | |||

| + | '''Applications :''' | ||

| + | - Heavy-duty gear drives | ||

| + | - Various industrial configurations | ||

| + | |- | ||

| + | ![[File:TNA (Two-Row Non-Adjustable).jpg|center|frameless]]TNA (Two-Row Non-Adjustable) | ||

| + | |TNA bearings are similar to the TDO, but the inner race narrow faces are extended to abut and eliminate the need for a separate inner race spacer. Supplied with an in-built clearance to give a standard setting range, these bearings provide a solution for many fixed or floating bearing applications where simplicity of assembly is required. | ||

| + | |||

| + | |||

| + | '''Size range :''' | ||

| + | |||

| + | - ID 25.400 mm to 1200.150 mm (1.0000 in. to 47.2500 in.) | ||

| + | |||

| + | - OD 30.480 mm to 2460.000 mm (1.2000 in. to 96.8504 in.) | ||

| + | |||

| + | '''Design Attributes :''' | ||

| + | |||

| + | - Double cup and two single cones. | ||

| + | |||

| + | - Internal bearing clearance controlled by extending the front faces of the cones so they contact each other. | ||

| + | |||

| + | - SW variation features chamfers in the bores at the front faces of the two single cones to form a lubrication groove. | ||

| + | |||

| + | - SE variation features a back face rib design to accommodate radial lip seals or stamped closure. | ||

| + | |||

| + | '''Applications :''' | ||

| + | |||

| + | - Sheaves, Crane sheaves, Oil-field drilling rig sheaves, Applications where two-row preset bearings are required | ||

| + | |- | ||

| + | ![[File:SR (Two-Row Non-Adjustable).jpg|frameless]] | ||

| + | SR (Two-Row Non-Adjustable) | ||

| + | |SR bearings are made to a standard setting range, based on Timken’s Set-Right™ automated setting technique, and are suitable for most industrial applications. They have two spacers and an optional snap-ring for axial location. Because both types are made from popular sizes of single-row bearings, they provide a low-cost choice for many applications. | ||

| + | |||

| + | |||

| + | '''Size range :''' | ||

| + | |||

| + | - ID 26.987 to 200.000 mm (1.0625 in. to 7.8740 in.) | ||

| + | |||

| + | - OD 61.999 to 300.000 mm (2.4409 in. to 11.811 in.) | ||

| + | |||

| + | '''Design Attributes :''' | ||

| + | |||

| + | - Two TS bearings mounted indirectly with cone and cup spacers. | ||

| + | |||

| + | - Cup spacer features lubrication slots to allow commercial snap rings to locate bearings axially. | ||

| + | |||

| + | - Two J-Line™ Class N bearings with metric envelop and non-metric internal geometry. | ||

| + | |||

| + | '''Applications :''' | ||

| + | |||

| + | - Automotive configurations | ||

| + | |- | ||

| + | ![[File:2TS-IM (Spacer Assembly with Indirect Mounting).jpg|frameless]] | ||

| + | 2TS-IM (Spacer Assembly with Indirect Mounting) | ||

| + | |2TS-IM assemblies are comprised of two single-row bearings with an inner and outer ring spacer. In some applications, a shoulder in the bearing housing replaces the outer ring spacer. | ||

| + | |||

| + | |||

| + | '''Design Attributes :''' | ||

| + | |||

| + | - Steel spacers are used to create Bench End Play (BEP) or Preload (BPL) in the bearing assembly. | ||

| + | |||

| + | - Available with or without spacers. | ||

| + | |||

| + | - Spacers preset during manufacture. | ||

| + | |||

| + | '''Applications :''' | ||

| + | |||

| + | - Gear reduction units, Industrial machines | ||

| + | |- | ||

| + | ![[File:2TS-DM (Spacer Assembly with Direct Mounting).jpg|center|frameless]]2TS-DM (Spacer Assembly with Direct Mounting) | ||

| + | |2TS-DM assemblies are comprised of two single-row bearings with abutting back facing inner rings and an outer ring spacer with lubricating holes is typical. These are generally used at fixed positions on rotating shaft applications. | ||

| + | |||

| + | |||

| + | '''Design Attributes :''' | ||

| + | |||

| + | - Two single row bearings, with or without a spacer. | ||

| + | |||

| + | - When spacers are used, bearing is furnished as a preset, matched assembly. | ||

| + | |||

| + | - Spacers available with or without lubricant grooves and holes. | ||

| + | |||

| + | '''Applications :''' | ||

| + | |||

| + | - Gear reduction units, Industrial machines | ||

| + | |- | ||

| + | ![[File:TSRB (Snap-ring cup).jpg|alt=2TS-TM (Spacer Assembly with Tandem Mounting)|frameless]] | ||

| + | 2TS-TM (Spacer Assembly with Tandem Mounting) | ||

| + | |Where combined radial and thrust load capacity is required, but the thrust component is exceptional and beyond the capacity of a single bearing (within a given maximum OD), two single-row bearings can be mounted in tandem. Appropriate inner and outer ring spacers are supplied. | ||

| + | '''Size range :''' | ||

| + | |||

| + | 0 to 8 inches (Larger sizes available on request) | ||

| + | |||

| + | '''Design Attributes :''' | ||

| + | |||

| + | - Steel spacers are used to create Bench End Play (BEP) or Preload (BPL) in the bearing assembly. | ||

| + | |||

| + | - Spacers preset during maintenance. | ||

| + | |||

| + | '''Applications :''' | ||

| + | |||

| + | Hydrostatic axial piston pumps and motors | ||

| + | |} | ||

| + | |||

| + | === Metric Double Row === | ||

| + | Timken features one of the industry's largest selections of metric tapered roller bearing matched assemblies. With industry standard part numbering, it's now easier to find the bearing you need. | ||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ![[File:Metric Double Row.jpg|frameless]] | ||

| + | Metric Double Row | ||

| + | |Timken metric tapered roller bearing matched assemblies consist of two single-row bearings with individually matched spacers that are set at the factory to pre-determined dimensions and tolerances. Matched bearing assemblies are used in applications requiring higher load carrying capacity or where the shaft must be located axially in both directions with a specific axial clearance or preload. Timken offers a wide range of sizes and configurations and follows industry standard part numbering system for easy interchanges. Please see the Timken Metric Tapered Roller Bearings Matched Bearing Assemblies catalog below for product tables and part-numbering system information. | ||

| + | |||

| + | |||

| + | |||

| + | '''Design Attributes :''' | ||

| + | |||

| + | - Assemblies are available in both the direct (DF) and indirect (DB) mounting arrangements to meet application needs. | ||

| + | |||

| + | - The standard range of assemblies are specified with a market standard axial clearance value (Bench End Play). Application specific axial clearance values are available upon request. | ||

| + | |||

| + | - The standard outer ring spacer is designed with lubrication holes to allow for lubricant flow into both bearing rows.Assemblies are ready-to-fit into customer applications, with a unique serial number market on spacers and bearing components for easy identification. | ||

| + | |||

| + | All single-row metric tapered roller bearing components are designed according to the ISO 355 standard. | ||

| + | |||

| + | '''Applications :''' | ||

| + | |||

| + | - Gear drives and transmissionsCement pulverizers, Coal conveyors, Cranes, Calender rolls and more industrial applications | ||

| + | |} | ||

| + | |||

| + | = Four Row Bearing = | ||

| + | Timken® four-row tapered roller bearings combine the inherent high-load radial/thrust capacity and direct/indirect mounting variables of tapered roller bearings into assemblies offering maximum load rating in minimum space. | ||

| + | {| class="wikitable" | ||

| + | |- | ||

| + | ![[File:Four Row Bearing.jpg|frameless]] | ||

| + | TQO (Straight Bore Four-Row Assembly) | ||

| + | |TQO bearings are directly mounted and comprised of two double inner races, two single and one double outer race, with an inner race spacer and two outer race spacers. Slots in the inner race spacer permit lubricant to flow from the bearing chamber to the roll neck. The inner race spacers are hardened to minimize face wear. | ||

| + | |||

| + | |||

| + | '''Size range :''' | ||

| + | |||

| + | - ID 50.800 mm to 1500.000 mm (2.0000 in. to 59.0551 in.) | ||

| + | |||

| + | - OD 83.337 mm to 2032.000 mm (3.2810 in. to 80.0000 in.) | ||

| + | |||

| + | '''Design Attributes :''' | ||

| + | |||

| + | - Two double cones, two single cups and a double cup with a cone spacer and two cup spacers. | ||

| + | |||

| + | - Spacers have slots or holes for lubrication. | ||

| + | |||

| + | - Cone spacers are hardened to reduce face wear. | ||

| + | |||

| + | - Numbered serially to assure correct installation sequence. | ||

| + | |||

| + | '''Applications :''' | ||

| + | |||

| + | - Low- and medium-speed rolling mills | ||

| + | |- | ||

| + | ![[File:Four Row Bearing.jpg|frameless]] | ||

| + | TQOW (Straight Bore with Cone Face Lubrication Slots) | ||

| + | |TQOW bearings are similar to TQO bearings. When the fillet and/or filler rings do not already have lubrication slots, they are provided in the faces of the bearing inner race. | ||

| + | |||

| + | |||

| + | '''Size range :''' | ||

| + | |||

| + | - ID 50.800 mm to 1499.872 mm (2.0000 to 59.0501 in.) | ||

| + | |||

| + | - OD 83.337 mm to 2032.000 mm (3.2810 in. to 80.0000 in.) | ||

| + | |||

| + | '''Design Attributes :''' | ||

| + | |||

| + | - Similar to TQO, except that the cone faces have lubrication slots at each face. | ||

| + | |||

| + | - Two double cones, two single cups and a double cup with a cone spacer and two cup spacers. | ||

| + | |||

| + | - Cone spacers are hardened to reduce face wear. | ||

| + | |||

| + | - Numbered serially to assure correct installation sequence. | ||

| + | |||

| + | '''Applications :''' | ||

| + | |||

| + | - Low- and medium-speed rolling mills | ||

| + | |- | ||

| + | ![[File:Four Row Bearing.jpg|frameless]] | ||

| + | TQIT (Tapered Bore Four-Row Assembly) | ||

| + | |Type TQIT bearings have a tapered bore that is matched and continuous through the inner races. This allows for an interference fit on the backup rolls of high-speed mills, where a loose inner race fit of a straight bore bearing could cause excessive neck wear. The indirect mounting of the bearing pairs increases the overall effective spread of the bearing, providing optimum stability and roll rigidity. | ||

| + | |||

| + | |||

| + | '''Size range :''' | ||

| + | |||

| + | - ID 123.022 mm to 1004.633 mm (4.8434 in. to 39.5525 in.) | ||

| + | |||

| + | - OD 174.625 mm to 2032.000 mm (6.8750 mm to 80.0000 in.) | ||

| + | |||

| + | '''Design Attributes :''' | ||

| + | |||

| + | - Two tapered-bore single cones, one tapered-bore double cone, four single cups and three cup spacers. | ||

| + | |||

| + | - Front faces of single cones and both faces of double cone are extended to contact each other. | ||

| + | |||

| + | - Tapered cone bores are matched for continuous taper through the cones. | ||

| + | |||

| + | - Lubrication delivered through three cup spacers. | ||

| + | |||

| + | - Preset, matched assemblies, serial numbered to assure correct installation. | ||

| + | |||

| + | '''Applications :''' | ||

| + | |||

| + | - Roll necks of high-speed rolling mills | ||

| + | |- | ||

| + | ![[File:Four Row Bearing.jpg|frameless]] | ||

| + | SRNB (Sealed Four-Row Bearing) | ||

| + | |Timken® sealed roll neck bearings provide strength where it counts for flat product rolling mills. Our premium quality four-row sealed bearings are designed to operate at high speeds and withstand harsh environments, even while carrying heavy loads. | ||

| + | Built with highly rated Timken® tapered roller bearings, our sealed roll neck bearings are expected to provide a lower cost of ownership due to less required maintenance and longer bearing life. Timken case-carburized, high-capacity tapered roller bearings offer durable toughness. | ||

| + | |||

| + | The newest Timken sealed roll neck bearing is the integrated seal design that exemplifies our focus on advancing technology for the metals industry. Also available are the seal carrier design, many special designs and custom designs. | ||

| + | |||

| + | '''Size range :''' | ||

| + | |||

| + | - ID: 195.000 mm to 710.550 mm (7.6772 in. to 28.2500 in.) | ||

| + | |||

| + | - OD: 270.000 to 946.150 mm (10.6300in. to 37.2500 in.) | ||

| + | |||

| + | '''Design Attributes :''' | ||

| + | |||

| + | - Four single cups for optimum load sharing. | ||

| + | |||

| + | - Cup spacers available with or without lube groove and holes. | ||

| + | |||

| + | - Improved surface finishes to enhance lubrication performance. | ||

| + | |||

| + | - Inboard and outboard cone face slots that reduce cone face wear. | ||

| + | |||

| + | - Spiral bore grooves with blended radii to eliminate roll neck damage. | ||

| + | |||

| + | - Case-carburized components to improve toughness and increase fatigue life. | ||

| + | |||

| + | - Patented seal designs with improved contact geometry for enhanced sealing. | ||

| + | |||

| + | - Enhanced roller profiling for even load distribution, which reduces edge stress. | ||

| + | |||

| + | - No central cone or cup spacers to minimize number of components to be handled. | ||

| + | |||

| + | - Effective sealing at cup outer diameter (OD) to seal contaminants away from bearing OD and chock bore. | ||

| + | |||

| + | '''Applications :'''- Rolling mills | ||

| + | |} | ||

| + | |||

| + | = Integrated Bearing Assemblies = | ||

| + | Timken® integrated bearing assemblies are the result of our collaborations with customers to design, engineer and test a continuous stream of next-generation solutions, including AP-2™ bearings for rail applications. | ||

| + | {| class="wikitable" | ||

| + | ![[File:AP Integrated Bearing Assemblies.jpg|frameless]] | ||

| + | AP Integrated Bearing Assemblies | ||

| + | |This self-contained, pre-assembled and pre-lubricated bearing design is a rail industry standard. It reduces maintenance costs, delivers more miles per bearing and improves fuel efficiency. | ||

| + | |||

| + | |||

| + | '''Design Attributes :''' | ||

| + | |||

| + | -Self-contained, pre-assembled and pre-lubricated | ||

| + | Reduces maintenance costs, increases miles per bearing and fuel efficiency | ||

| + | |||

| + | - Industry standard | ||

| + | |||

| + | '''Applications :''' | ||

| + | |||

| + | Passenger Cars,Locomotives | ||

| + | |- | ||

| + | ![[File:AP-2 Integrated Bearing Assemblies.jpg|frameless]] | ||

| + | AP-2 Integrated Bearing Assemblies | ||

| + | |Based on the design of the AP™ bearing, Timken’s AP-2™ rail bearing is designed for heavier loads. It reduces bearing set outs fuel cost and bearing failure due to water ingress. It also reduces component wear rejection and axle fillet damage, decreasing potential axle failure and ultimately reducing the occurrence of axle grooving. | ||

| + | |||

| + | |||

| + | |||

| + | '''Design Attributes :''' | ||

| + | |||

| + | - Reduces bearing failure due to water ingress | ||

| + | |||

| + | - Reduces bearing set outs | ||

| + | |||

| + | - Reduces fuel costs | ||

| + | Reduces component wear rejection | ||

| + | |||

| + | - Reduces axle fillet damage | ||

| + | |||

| + | - Decreases potential axle failure | ||

'''Applications :''' | '''Applications :''' | ||

| − | - | + | Rail – Freight Cars |

| + | |- | ||

| + | ![[File:Formed Hub™ Wheel End System.jpg|frameless]] | ||

| + | Formed Hub™ Wheel End System | ||

| + | |Timken® Formed Hub™ is an integrated wheel bearing assembly that can bolt directly onto corners, eliminating the need for conventional components like washers, spacers and nuts. The design enables lower total system cost, commonization opportunities, improved performance, reduced weight and lower warranty costs. | ||

| + | |||

| + | |||

| + | '''Design Attributes:''' | ||

| + | |||

| + | - Designed with nearly 75% fewer components, reducing assembly time and lowering costs for sourcing, inventory and assembly. | ||

| + | |||

| + | - Engineered for driven and non-driven wheels, replacing the conventional 4×2 (dead) spindle. | ||

| + | |||

| + | - Features an advanced sensor and sensor technology for superb performance. | ||

| + | |||

| + | - Holds bearing setting more consistently than traditional thread and nut designs. | ||

| + | |||

| + | - The resulting system stiffness reduces rotor runout and improves brake performance. | ||

| + | |||

| + | - Reduces weight by up to 20% per assembly compared to conventional wheel end solutions. | ||

| + | |||

| + | - Self-clamped design eliminates high stress in the spindle and CV joint, reducing overall warranty costs caused by bearing wear and failure. | ||

| + | |||

| + | |||

| + | '''Applications:''' | ||

| + | |||

| + | - Light vehicles and light trucks (original equipment) | ||

| + | |- | ||

| + | ![[File:Generation 3 Hub & Bearing Assembly.jpg|frameless]] | ||

| + | Generation 3 Hub & Bearing Assembly | ||

| + | |The Generation 3 hub and bearing assembly is an integrated bearing assembly that offers design flexibility and bolt-on simplicity and features active sensing technology. Generation 3 improves stiffness and brake performance, reduces weight and envelope size, lowers assembly costs and reduces warranty claims. | ||

| + | Design Attributes: | ||

| + | Integrated raceway and hub increases stiffness as much as 30 percent over conventional systems. Also eliminates the discrete race variables between the bearing and hub, providing a closer preload setting range. | ||

| + | Narrow overall package width and reduced radial section thickness lowers unsprung weight, improving vehicle maneuverability and fuel efficiency. | ||

| + | Features a pre-sealed, pre-greased and pre-set bearing package design with integrated sensing technology for anti-lock braking systems, total traction control and vehicle dynamics systems. | ||

| + | Hub-forming technology reduces strain on components and the costs associated with purchased parts and labor. Also allows for commonization between driven and non-driven designs. | ||

| + | Fully serviceable wheel speed sensor is internally mounted and protected from road hazards, debris and potential damage. | ||

| + | Applications: | ||

| + | Light trucks and sport utility vehicles (original equipment and aftermarket) | ||

| + | |- | ||

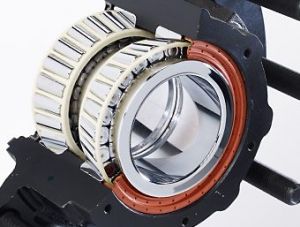

| + | ![[File:Pinion-Pac™.jpg|frameless]] | ||

| + | Pinion-Pac™ | ||

| + | |Pinion-Pac™ is a ready-to-install, pre-sealed, pre-set tapered roller bearing unit that simplifies axle assembly and improves system performance in light duty automotive applications. Customers rely on Pinion-Pac for improved gear reliability and bearing life; reduced noise, vibration and harshness (NVH); reduced weight and fewer warranty claims. | ||

| + | Design Attributes: | ||

| + | Tighter manufacturing tolerances provide better concentricity and optimum bearing setting for improved gear mesh contact and longer bearing life. | ||

| + | Stiff design reduces deflection at the gear mesh point during dynamic loading conditions, improving gear reliability. | ||

| + | Compact design can result in an overall weight reduction of up to 15 percent – translating into better handling and increased fuel efficiency. | ||

| + | Self-contained package reduces the need for bearing assembly tooling and can eliminate 45 percent of the components that need stocked for conventional designs. | ||

| + | Improved concentricity of the seal riding surface on the bearing inner race results in less seal wear, reducing warranty claims. | ||

| + | Package design simplifies axle repair — maintenance shops can keep fewer replacement parts on hand and technicians will spend less time on installation. | ||

| + | Applications: | ||

| + | Light trucks and sport utility vehicles (original equipment) | ||

| + | |- | ||

| + | ![[File:Lightweight RacePac® Front and Rear Wheel End Assemblies.jpg|frameless]] | ||

| + | Lightweight RacePac® Front and Rear Wheel End Assemblies | ||

| + | |For stronger performance, we re-engineered RacePac wheel end assemblies to enhance speed and performance on all types of tracks while increasing your team’s efficiency in the shop. | ||

| + | Design Attributes: | ||

| + | Timken® RacePac® Tapered Roller Bearings* | ||

| + | 30% cooler operating temperatures**: Improved internal geometry reduces sliding contact stress and provides consistent rolling torque. | ||

| + | Reduce bearing replacement costs: Enhanced durability due to lower operating temperatures. | ||

| + | Improved drivetrain efficiency: Reduced bearing power loss results in a cooler running hub. | ||

| + | Ready to install: Bearings pre-lubed, pre-set and pre-assembled to Timken specifications. | ||

| + | Timken-Designed Zero-Torque Seal* | ||

| + | Excellent performance: Seal works off positive air pressure, keeping contaminants out. | ||

| + | More horsepower potential due to less seal drag. | ||

| + | Hubs | ||

| + | More speed: 2 pounds lighter (8 pounds total unsprung weight reduction). Meets minimum weight requirement of 6.25 lbs. | ||

| + | Durability maintained with lightweight design. | ||

| + | Grease Containment Dams | ||

| + | Maintain proper lubrication: Keeps grease in critical areas; additional grease dam in the rear hub helps reduce operating temperatures. | ||

| + | Engineered Spacers | ||

| + | Reduces setup time and increases stiffness: Precise design helps optimize bearing setting. | ||

| + | <nowiki>*</nowiki>Available exclusively in RacePac. ** Rear bearing rig testing. | ||

| + | Rear RacePac Enhanced and Tested for Stronger Performance | ||

| + | Benchmarked against the existing RacePac, we enhanced the robustness and conducted successful 12-hour internal rig tests. | ||

| + | History shows that successful testing is an indicator of stronger performance regardless of car setup or track. | ||

| + | Multiple tests completed designed to optimize grease fill, lubricant retention, bearing setting and enhanced bearing internal geometry. | ||

| + | More durable and lighter hub with less unsprung weight on the rear axle. | ||

| + | Reduces the amount of cooling needed for rear hubs which can enable additional aerodynamic adjustments. | ||

| + | |||

| + | Save Time and Costs with Our Dedicated RacePac Refurbishment Program | ||

| + | Our dedicated refurbishment program consists of: inspection, magnetic particle inspection, cleaning, replacement of necessary components, re-greasing and repackaging. We return completely refurbished RacePac wheel end assemblies to you – saving you time and costs. | ||

| + | Applications: | ||

| + | Professional stock car racing | ||

| + | |- | ||

| + | ![[File:Sensor-Pac Wheel Bearing Package.jpg|alt=Sensor-Pac Wheel Bearing Package|frameless]] | ||

| + | Sensor-Pac Wheel Bearing Package | ||

| + | |The first wheel bearing package to deliver the capability for total traction control under all conditions, Sensor-Pac is an integrated bearing assembly featuring an integral wheel speed sensing system designed to improve performance for anti-lock brake and traction control systems. | ||

| + | Design Attributes: | ||

| + | Pre-set, pre-greased and pre-sealed. | ||

| + | Features an active sensor capable of sensing down to zero speed. Sensor’s speed information is used for vehicle dynamics control systems, speed control, speedometer, odometer, trip computer and other purposes. | ||

| + | Sensor-Pac utilizes extremely small sensor-to-target wheel gaps, enabling a much smaller and more cost-effective sensor. | ||

| + | Sensor mounted internally for protection against debris, corrosion, thermal shock, and other hazards that threaten externally-mounted sensors – helping reduce warranty costs. | ||

| + | Sensor will operate without compromise, despite temperature extremes or prolonged braking conditions. | ||

| + | Designed for superior performance in a minimal space. Timken engineers have packaged the sensor within the bearing without increasing overall dimensions to promote high performance and equal load carrying capacity in a small space. | ||

| + | Applications: | ||

| + | Light vehicles (original equipment) | ||

| + | |- | ||

| + | ![[File:Sheave Pac Bearing Assembly for Oil & Gas Drilling Rigs.jpg|frameless]] | ||

| + | Sheave Pac Bearing Assembly for Oil & Gas Drilling Rigs | ||

| + | |The Timken® Sheave Pac® bearing assembly provides an innovative maintenance solution for oil and gas drilling rig crown and traveling blocks and riser tensioners. Preset, pre-greased, and unitized, Timken Sheave Pac helps improve employee safety, increase uptime, simplify installation and virtually eliminates maintenance. | ||

| + | '''Design Attributes :''' | ||

| + | - Preset, pre-greased, assembled and sealed at the factory – eliminating the risk of improper bearing setting and contamination and reduces the potential for bearing damage. | ||

| + | |||

| + | - Unitized assembly contains the bearing cones, bearing cup, triple-lip seals and grease – simplifying installation. | ||

| + | |||

| + | - “Sealed-for-life” design eliminates frequent inspections and re-lubrication – improving employee safety, uptime and productivity. | ||

| + | |||

| + | - Dimensionally interchangeable with current industry-standard bearing assemblies and seals, requiring no modification of the sheave bore. | ||

| + | |||

| + | - Designed to operate within existing industry-standard snap ring and groove dimensions. | ||

| + | '''Applications :'''- Crown and traveling blocks and riser tensioners – On and Off Shore Oil and Gas Drilling Rigs | ||

| + | |- | ||

| + | ![[File:Timken UltraWind Tapered Roller Bearings.jpg|frameless]] | ||

| + | Timken UltraWind Tapered Roller Bearings | ||

| + | |With the highest life ratings in the industry verified by Germanischer Lloyd, the new UltraWind series of bearings provides a cost-conscious, simplified drive train for main-shaft wind turbine designs (both gear and gearless). | ||

| + | Ideal for original equipment manufacturers developing multi-megawatt wind turbine designs, the Timken® UltraWind tapered roller bearing optimizes drive train simplicity, reliability and performance. It features a customized main-shaft bearing system approach that combines either a double-row tapered roller bearing or two, single-row tapered roller bearings with seals, lubrication and condition monitoring. | ||

| + | Bearing designs can accommodate most styles of wind turbine designs with variable bolt circles, shaft-mounted and shaftless designs, rotating inners and outers, gear and gearless wind turbines. | ||

| + | '''Design Attributes:'''- Simplified, compact drive train design saves capital equipment costs | ||

| + | - Pre-set internal clearance facilitates ease and accuracy of the assembly | ||

| + | |||

| + | - Pre-loaded bearing designed for superior stiffness to manage motion of the main shaft and rotor | ||

| + | |||

| + | - Bearing raceway profiles control maximum stress levels to provide greater product durability | ||

| + | |||

| + | - Optimized cage designs, including steel and polymer configurations, improve capacity and roller retention | ||

| + | |||

| + | - Features the highest bearing life ratings in the industry as certified by Germanischer Lloyd | ||

| + | '''Applications:''' | ||

| + | - Wind turbine main-shaft bearing for turbines, with or without gearbox | ||

| + | |- | ||

| + | ![[File:UniPac.jpg|frameless]] | ||

| + | UniPac™ | ||

| + | |The Timken® UniPac™ is a two-row tapered roller bearing package fitted with advanced seals and lubricated with the latest in premium multi-purpose grease. UniPac is used in medium-duty and commercial vehicle applications where weight reduction is essential. | ||

| + | '''Size range :'''- Standard bore sizes: 68mm, 78mm, 82mm and 90mm. Other sizes available upon request. | ||

| + | '''Design Attributes :''' | ||

| + | - Pre-set, pre-sealed and pre-lubricated bearing package eliminates the need for manual bearing adjustment and features fewer components, simplifying installation and maintenance. | ||

| + | - Features a reduced bearing setting range for increased bearing and system life. | ||

| + | - Design optimizes weight and packaging for high power density – greater performance in a smaller package. | ||

| + | - Additional design options include through hardened or case carburized steel, standard or super-sealed grease and oil lubrication. | ||

| + | '''Applications :'''- Medium-duty and commercial vehicle truck and trailer wheel ends (original equipment) | ||

| + | |- | ||

| + | ![[File:Wheel-Pac™.jpg|frameless]] | ||

| + | Wheel-Pac™ | ||

| + | |The Timken Wheel-Pac bearing is a pre-set, pre-greased, pre-sealed integrated bearing assembly that provides outstanding wheel end performance for commercial vehicle trucks and trailers. We customized Wheel-Pac to suit the truck builder’s preferred hub design. | ||

| + | '''Design Attributes :''' | ||

| + | - Pre-set, pre-greased and pre-sealed bearing package eliminates the need for manual bearing adjustment and features fewer components, simplifying installation and maintenance. | ||

| + | |||

| + | - Features a reduced bearing setting range that reduces runout, increases assembly stiffness and provides better friction control for increased system life. | ||

| + | |||

| + | - Design optimizes weight and packaging for high power density – greater performance in a smaller package. | ||

| + | |||

| + | - Additional design options include through hardened or case carburized steel (for improved debris resistance), greased, super-sealed or oiled lubrication options, and anti-lock braking systems ring integration. | ||

| + | '''Applications :'''- Commercial vehicle truck and trailer wheel ends (original equipment) | ||

|} | |} | ||

| − | = | + | = Precision Tapered Roller = |

| + | We produce Timken[register] precision tapered roller bearings in both inch and metric sizes to meet the full range of precision application requirements. They are engineered for superior accuracy and control – every time. | ||

Latest revision as of 23:07, 31 August 2022

Single Row Bearing[edit | edit source]

Inch Single Row[edit | edit source]

Single-row tapered roller bearings are the most basic and widely used, consisting of a cone assembly and a cup. Timken patented the first in 1898 and today offers the world's widest variety in inch and metric sizes.

Metric Single Row[edit | edit source]

The company continues to extend its line of Timken® single row metric tapered roller bearings to respond to customer needs and today offers one of the industry's broadest ranges of metric parts.

Double Row Bearing[edit | edit source]

Inch Double Row[edit | edit source]

Double- or two-row Timken® tapered roller bearings feature double cups and two single cones. They are available in a variety of configurations for general industrial and automotive applications.

Metric Double Row[edit | edit source]

Timken features one of the industry's largest selections of metric tapered roller bearing matched assemblies. With industry standard part numbering, it's now easier to find the bearing you need.

Four Row Bearing[edit | edit source]

Timken® four-row tapered roller bearings combine the inherent high-load radial/thrust capacity and direct/indirect mounting variables of tapered roller bearings into assemblies offering maximum load rating in minimum space.

Integrated Bearing Assemblies[edit | edit source]

Timken® integrated bearing assemblies are the result of our collaborations with customers to design, engineer and test a continuous stream of next-generation solutions, including AP-2™ bearings for rail applications.

Precision Tapered Roller[edit | edit source]

We produce Timken[register] precision tapered roller bearings in both inch and metric sizes to meet the full range of precision application requirements. They are engineered for superior accuracy and control – every time.